Online catalogue - Vacuum pumps

Online catalogue - COAX® cartridges

Online catalogue - Suction cups

CAD download centre

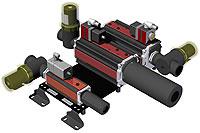

The vacuum pumps have become so small that they can be placed straight at the very place of suction in so-called integrated vacuum grippers. These increase the speed of the system by minimizing the amount of air that must be evacuated. Adaptation to the application is thus simplified by the use of the small and lightweight vacuum grippers.

Multi-stage ejector

PIAB vacuum pumps are of the multi-stage ejector type – a technology patented by PIAB in 1973.

These vacuum pumps were developed to provide extra vacuum flow in combination with deep maximum vacuum levels while keeping energy consumption at a minimum.

PIAB pumps have no moving parts that vibrate or wear out – important features that contribute heavily to outstanding operational reliability and a pleasant, noise-free working environment.

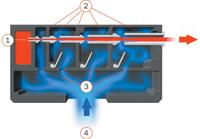

Principle of PIAB vacuum pumps

PIAB vacuum pumps are compressed air-driven vacuum pumps. The unique construction makes maximum use of the compressed air and therefore consumes less energy. Large vacuum flows and high levels of vacuum are characteristic of PIAB’s vacuum pumps.

When compressed air (1) passes through the nozzles (2), air is pulled through with the stream of compressed air. “Suction” is thus created at the opening of each stage (3), resulting in low pressure, vacuum (4).

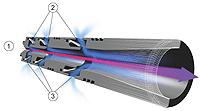

COAX® technology

PIAB's patent technology platform is an offshoot of the multistage

technology.

COAX® ensures excellent performance at both low and high feed pressures –

ideal for situations where compressed air lines deliver air at low or

fluctuating pressures.

Pumps based on the COAX® technology can operate within the range of 0.17

to 0.60 MPa.

Principle of the COAX® technology

Our latest technology is derived from the multi-stage ejector principle. Note that both a filter and check valves are integrated into the ejector section.

When compressed air (1) passes through the nozzles (2), air is pulled through with the stream of compressed air. “Suction” is thus created at the opening of each stage (3).

For more information on COAX® technology,

please visit our website www.coaxtechnology.com.

DURAFLEX® — for increased productivity and performance Increase your productivity and security with DURAFLEX®, a strong and elastic material with excellent sealing capability. High friction and reduced micro-leakage increase the lifting capability and the cup’s outstanding wear resistance extends the change-over intervals. PIAB’s unique dual-hardness cups are ideally suited for applications where micro-leakage can occur, for example when a suction cup does not properly conform to a handled material, such as corrugated cardboard. Dual-hardness cups provide both the strength and flexibility needed to seal on uneven or coarse surfaces.

Powder materials are common in chemical industries and similar industries such as the food and pharmaceutical industries. Vacuum conveying is an unsurpassed means of satisfying the demanding requirements of cleanliness and hygiene.

10000000100000001100000010001000110011001100110011111111101010101111000011111111110011001000100011110000111100001100000010001000

|